In a bold move marked by significant restructuring, Tesla has initiated a major shift in its operational strategy following the dismissal of over 10,000 employees since April. The electric vehicle (EV) behemoth is setting its sights on reducing production costs, particularly for its much-anticipated Cybertruck and the popular Model Y.

This strategic pivot comes in the wake of appointing Bonne Eggleston as the new head of Tesla’s 4680 battery department, a change sparked by the departure of former SVP Powertrain and Energy Engineering, Drew Baglino.

Bonne Eggleston’s New Role and Strategy

Under the leadership of Bonne Eggleston, company’s 4680 battery division is undergoing a significant overhaul with the primary aim to slash production costs drastically. Eggleston, who confirmed his new role and objectives on social media platform X, has been tasked with an ambitious goal: making Tesla’s 4680 batteries more cost-effective than those offered by current suppliers, such as Panasonic and LG New Energy.

The urgency of this initiative is highlighted by company’s contingency plan, which includes potentially discontinuing the 4680 project if the cost reduction target is not met by year’s end.

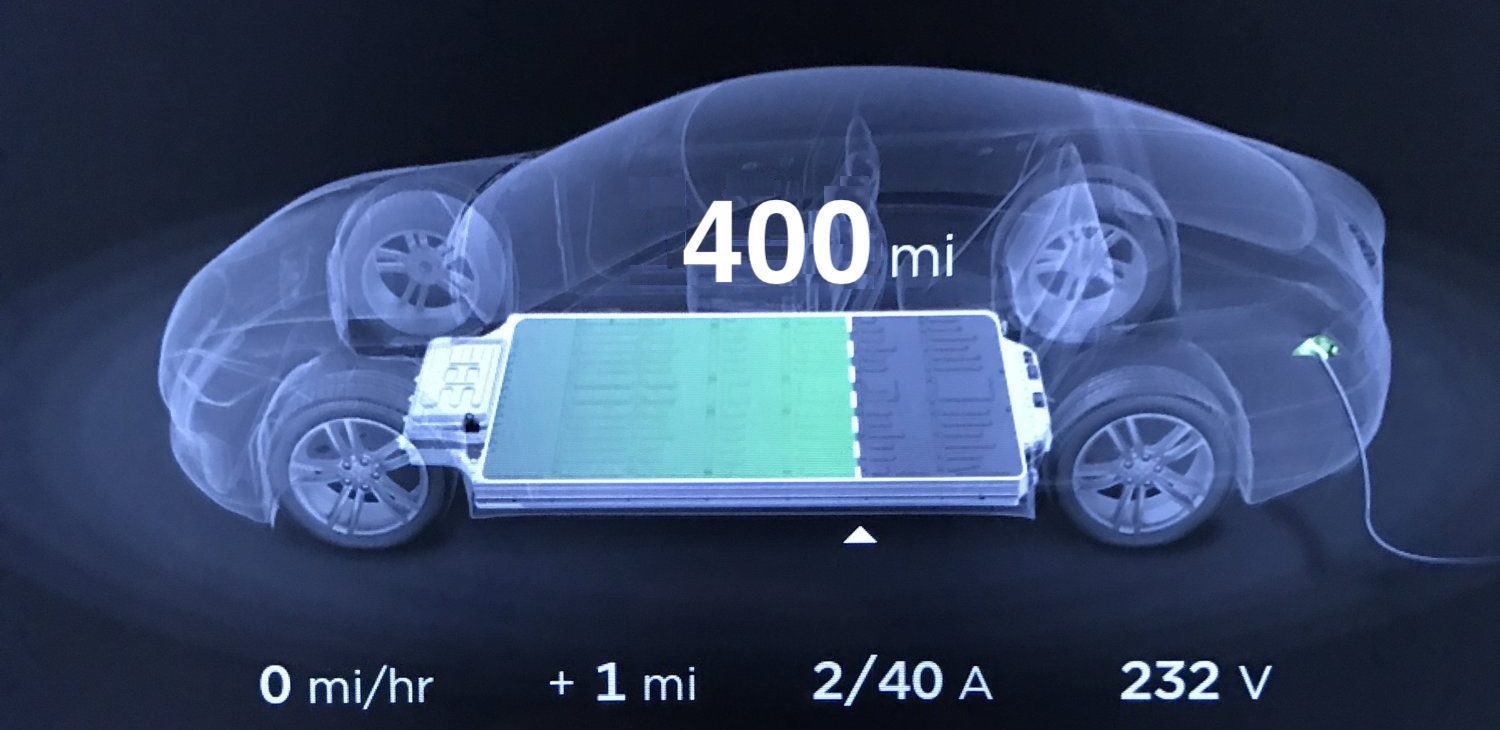

Tesla Battery Day, just wow.

54% Range Increase

56% $/kWh reduction

69% Factory cost reductionThis company is truly another breed.

$25,000 Tesla in a 3 years pic.twitter.com/uhmfq1AqAr

— Ken Kirtland IV (@KenKirtland17) September 22, 2020

The Road to Cost Reduction: Challenges and Innovations

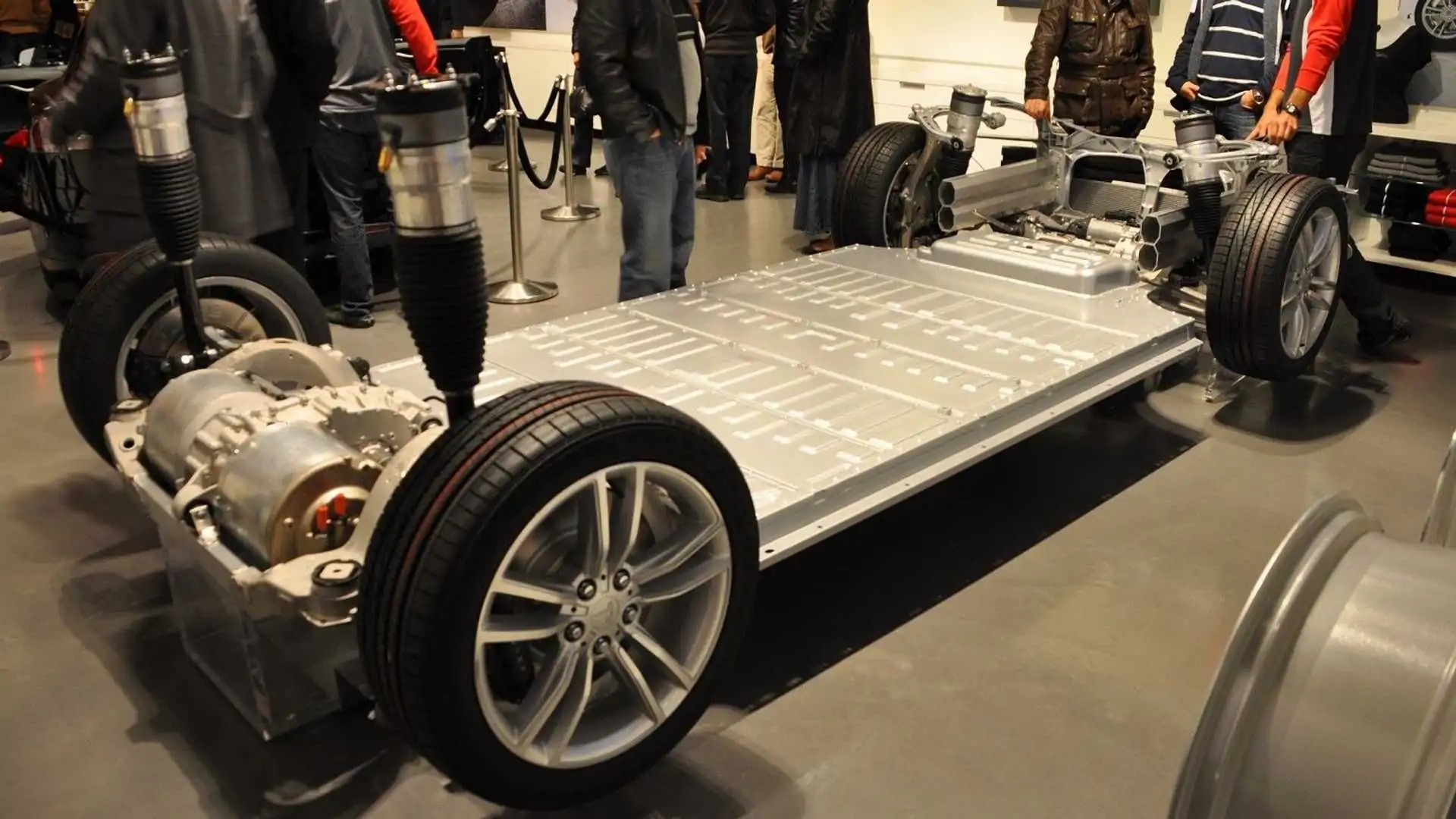

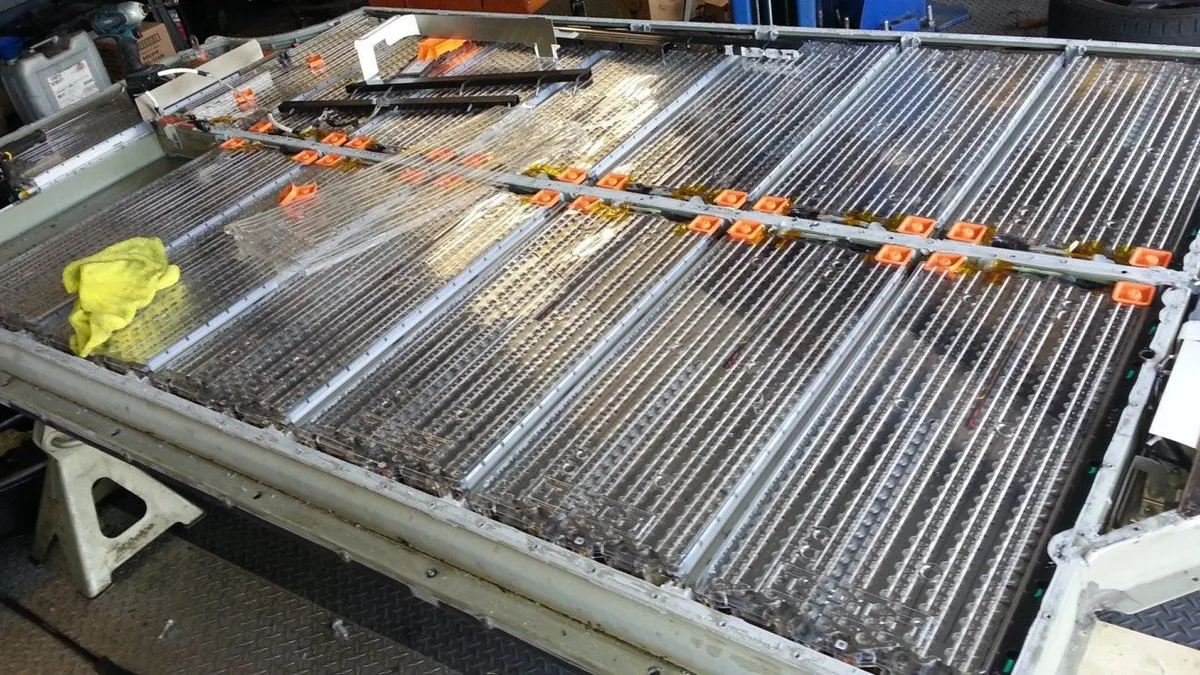

Achieving a 50% cut in battery costs is no small feat. company’s initial efforts have yielded a 20% cost reduction, leveraging the larger cell design of the 4680 batteries and their integration into the vehicle’s chassis. However, the company faces significant technological hurdles, particularly in mastering the dry-coated electrode production method, essential for further cost reductions.

Despite these challenges, Tesla remains focused on refining its production processes to maintain a competitive edge in the rapidly evolving EV market. This focus is crucial as Tesla navigates through a period marked by declining revenue and a drop in gross profit margins from car sales, the first in nearly four years.

Eggleston Faces Challenges as Tesla Shifts Battery Strategy

The task ahead for Eggleston and his team is daunting, especially with competitors like CATL and BYD, who are capable of producing batteries at lower costs. These competitive pressures are compounded by internal challenges, including the recent high-profile exits from Tesla’s senior management team.

The adjustments in company’s battery production strategy signify a crucial pivot point for the company. As Elon Musk continues to lead Tesla amid these turbulent times, the automotive world watches closely. The success or failure of Eggleston’s efforts could very well dictate company’s future in the EV market and influence how electric vehicles are powered in the future.

Stay tuned to Tech Times for more updates on company’s strategic shifts and how they aim to reshape the EV landscape.