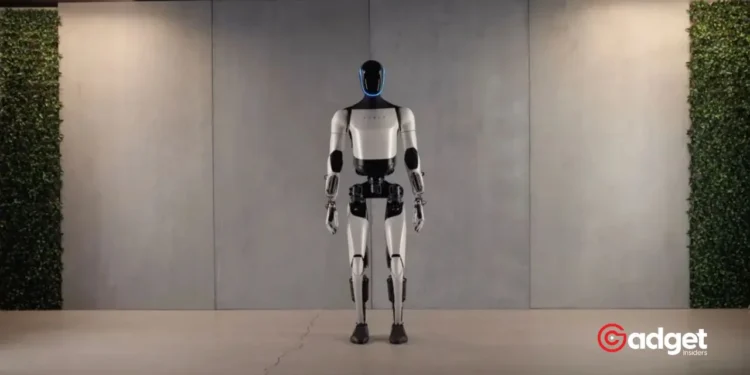

Tesla’s journey into robotics has taken another step forward with a recent showcase of its humanoid robot, Optimus. This sophisticated robot, designed for an array of factory tasks, now flaunts its ability to autonomously sort battery cells, among other tasks. As technology continues to evolve, Tesla’s Optimus robot represents a leap toward the future of automated factory work, illustrating not just what robots can do, but how they are evolving to perform tasks more efficiently and with greater precision.

Revolutionizing Factory Operations with Optimus

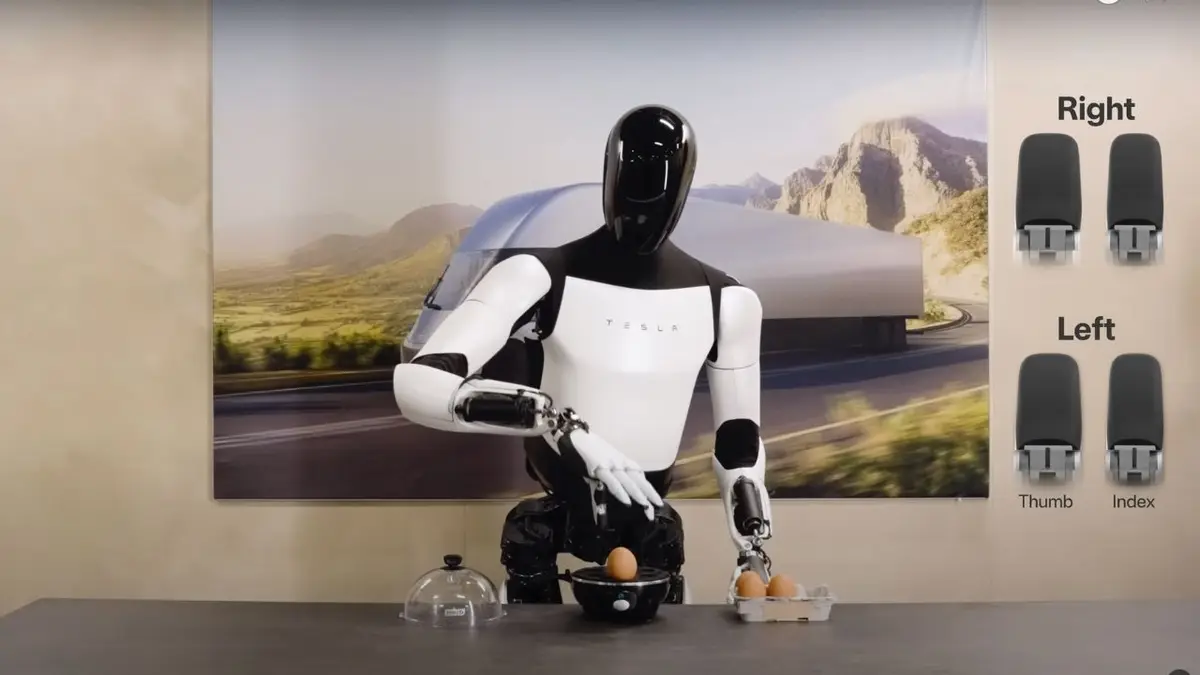

During a recent update shared through the Tesla Optimus X social media account, Optimus was seen performing various tasks autonomously in a Tesla factory setting. One of the standout capabilities displayed was its skill in sorting 4680 battery cells, a critical component in Tesla’s electric vehicle manufacturing process. The video proudly highlighted the robot’s ability to not only sort these cells efficiently but also correct its errors in real-time.

The new robot uses a sophisticated end-to-end neural network, combined with cameras, tactile sensors on its hands, and force sensors. These technologies enable the robot to perceive and interact with its environment with an unprecedented level of sophistication for industrial robots. Tesla has noted continual improvements in the robot’s operations, with decreasing needs for human intervention, showcasing the strides Tesla is making in autonomous technology.

The New Tesla Optimus robot video. Perhaps the best leaps forward for end-effector fine control, fluid moment and alignment.

It is quite impressive.

Congratulations Optimus team! pic.twitter.com/rXwc3iNTGb

— Brian Roemmele (@BrianRoemmele) May 5, 2024

A Stroll Through Innovation

The recent footage also captured Optimus taking a leisurely walk across the office. This demonstration of improved locomotion is a testament to Tesla’s commitment to enhancing the robot’s mobility and versatility within a working environment. Tesla’s continual updates reveal that the new robot’s walking rate and task precision are seeing significant advancements.

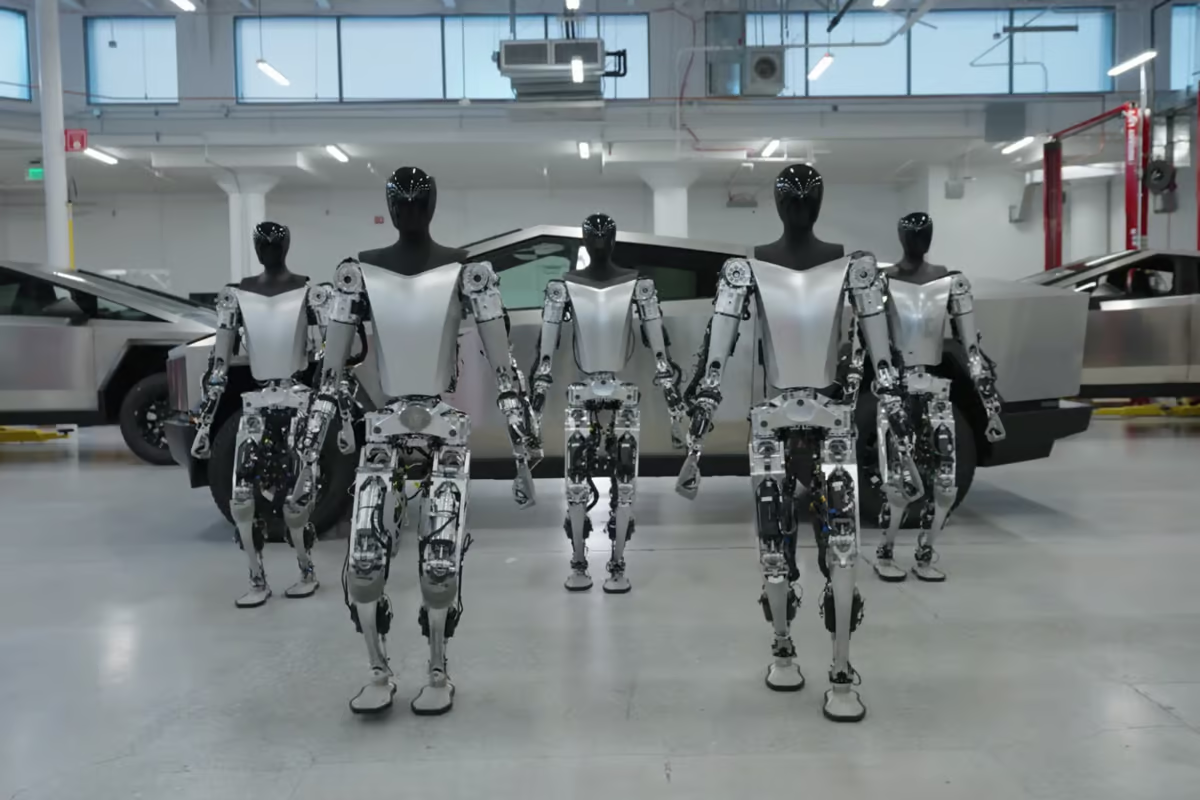

Elon Musk, Tesla’s CEO, shared insights during Tesla’s Q1 2024 earnings call, highlighting that Optimus is not just a prototype but is actively enhancing productivity in Tesla’s factories. Musk’s vision extends beyond internal use; he anticipates selling the robots externally by the end of 2025, potentially transforming industries beyond automotive manufacturing.

Affordable Robotics on the Horizon

In a bold move towards making advanced robotics more accessible, Musk has projected that the cost of an Optimus unit could drop to less than $25,000—less than half the price of a typical car. This pricing strategy could revolutionize the economic feasibility of integrating humanoid robots into both industrial and possibly consumer markets shortly.

A New Era of Technological Integration

Tesla’s Optimus robot is paving the way for the future of robotic assistance in industrial settings. With capabilities like sorting battery cells autonomously, walking, and even performing complex physical tasks such as yoga, the new robot is not just a tool but a harbinger of the future of work where robots and humans will increasingly collaborate in more integrated and productive ways.

Tesla continues to push the boundaries of what autonomous systems can achieve in real-world applications. As we watch the new robot evolve, the possibilities of what can be accomplished through robotics continue to expand, hinting at a future where the synergy between human ingenuity and robotic precision creates environments of unprecedented efficiency and innovation.