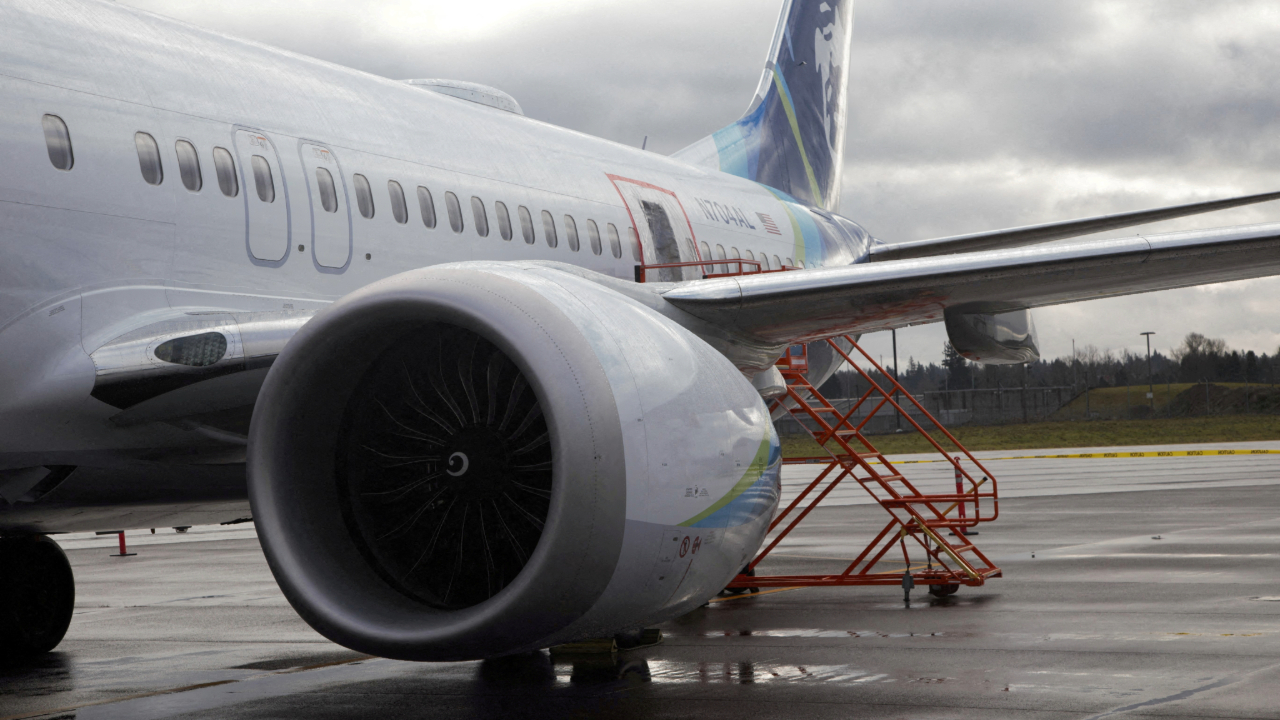

In an age where aviation safety is paramount, the recent findings from the Federal Aviation Administration’s (FAA) audit of Boeing’s 737 Max production process are not only startling but deeply concerning. The audit, prompted by an incident involving a door plug on a 737 MAX 9 aircraft, has revealed what the FAA has called “unacceptable” lapses in Boeing’s quality control measures.

With the aviation giant failing 33 out of 89 product audits, resulting in a shocking 97 instances of alleged noncompliance, the integrity of the company’s manufacturing process is now under the microscope.

Unconventional Practices and the Lapses Unearthed

At the heart of the FAA’s findings are practices that would seem out of place in the meticulous world of aircraft manufacturing. Among these was the observation of mechanics at Spirit AeroSystems (a key supplier for Boeing) using dish soap as a lubricant for door seals and a hotel key card to assess the integrity of these seals.

These practices, observed at Spirit’s fuselage manufacturing plant in Wichita, Kansas, highlight a concerning departure from the rigorous standards expected in aircraft production.

Spirit AeroSystems itself did not emerge unscathed, failing seven out of thirteen product audits. The audits pointed to issues ranging from vague instructions for mechanics to deficiencies in installing critical components, like the plane’s door plug.

Boeing and Spirit AeroSystems: Addressing the Nonconformities

In the wake of these findings, both Boeing and Spirit AeroSystems have been thrust into a period of introspection and corrective action. A spokesperson for Spirit AeroSystems emphasized the company’s commitment to reviewing and rectifying the identified non-conformities.

Meanwhile, the airplane manufacturing giant is now under the FAA’s directive to devise a comprehensive plan within 90 days to address the systemic quality control deficiencies unearthed by the audit.

The weeks-long audit is part of the FAA’s ongoing investigation following the January Alaska Airlines flight where a Boeing 737 Max 9 lost a door plug. Unbelievable! We need safety on all Airlines! https://t.co/aByp6y5lqn

— Loretta Madrigal (@LorettaFilms) March 14, 2024

A Broader Inquiry into Aviation Safety

The FAA’s investigation is just the tip of the iceberg. The National Transportation Safety Board and the Justice Department have launched their inquiries into the door panel blowout incident, signaling a broader concern over safety and compliance in Boeing’s 737 production line.

These investigations are a testament to the seriousness with which these lapses are being treated, underscoring the imperative of maintaining the highest standards of safety in the aviation industry.

A Wake-Up Call for Boeing and the Aviation Industry

The findings from the FAA’s audit serve as a critical wake-up call not just for Boeing but for the entire aviation industry. As the aeronautic company grapples with the fallout and works towards rectifying the highlighted issues, the broader implications for aviation safety standards and quality control are clear.

The industry must hold itself to the highest standards, ensuring that the safety of passengers and crew remains the unequivocal priority. With the world watching, the steps Boeing takes next will be crucial in restoring confidence in its commitment to quality and safety.